LEATHER

Leather is our first and main working material. In the form of skins, it was one of the first elements men used for dressing, and remains one of the most natural, flexible, comfortable, durable materials that can be used.

The leather comes from treated skin of different animals. We mainly use cowhide, because of its resilience and flexibility. Also sheep leather, softer and more flexible, but less resistant, or deer leather, very tough but something hard and less manageable.

For a skin to become leather has to pass a number of processes. The main among them is the tanning, which is the process that turnsfresh skin, withflesh, fat and rotability, into leather does not rot and is highly resistant.

There are two basic tanning products, vegetable products, mainly tannin (the name tannery comes from here) coming from different trees such as oak, chestnut or cherry, or through other mineral products such as chrome. Skin hair must also be removed, to turn into real leather, which is made by dipping in lime and scraping.

The leather can be left in natural colour, known as tanor raw, or can be dyed in different colours.

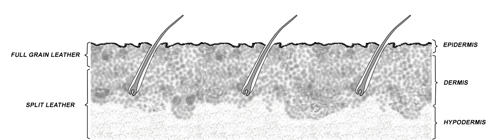

But before tanning and dyeing, several works are performed, some of which will give the leather specific names. Reduce the thickness is an important work. The animal skin is thick, and in some areas like the neck, especially thick. We can say that skin is between 5-8 mm thick and has three layers, the epidermis, dermis and hypodermis.

Therefore it must be reduce until it becomes uniform, and also nice and flexible. This is done by laminating the skin in different layers (what is called Split) until reaching the desired thickness, and removing from a thick skin several layers, receiving different names. The most quality is the topsheet that corresponds to the animal’s epidermis, and is called FULL-GRAIN leather. The lower sheetscorresponding to the hypodermis, are more fibrous, lower quality, but much more resistant, and are called SPLITS leather.

The ideal garment leather is the full-grain leather, and its thickness should be around the 0.8 mm.

To make nice tract leather, one of the sides is sand or polish. If sanded face is the outside (where the hair was) is called NOBUCK leather. The Nobuck is very pleasant, as it has a velvety touch, it is flexible but durable, so it’s used for clothing and footwear making. If sanded face is the interior (which contacted with fat and flesh), is called SUEDE leather. Suede is very soft and pleasant, but less resistant, so it is used for delicate garments and gloves.